Machining

Manual Milling

We have several manual machines to fit most needs. We have both vertical and horizontal manual mills that can accommodate parts up to around 600 lbs. These machines are perfect for doing cost-effective repairs to broken parts, for example, lawn mower (or even truck) engine parts, custom electronics enclosures, electrical motor repair/modification, cylinder head resurfacing, or manufacture of new parts. Many times cost can be cut by combining our CNC and manual machine services for a part.

If you are unsure if this is right for you, contact us and we can answer any questions you have.

CNC Milling

Our 3 axis CNC machine can produce intricate and precise parts that manual machines cannot always do, and if they can they are often much more expensive using traditional methods. With our in-house CAD design, we can design and produce any part you can think of given it fits within the machine, which is perfect for prototyping or making custom parts. Our machine can take parts that weigh up to 1000 LBS and has a 57.75" x 10.5" table with 40" x 16" x 16" travel.

For more information please contact us.

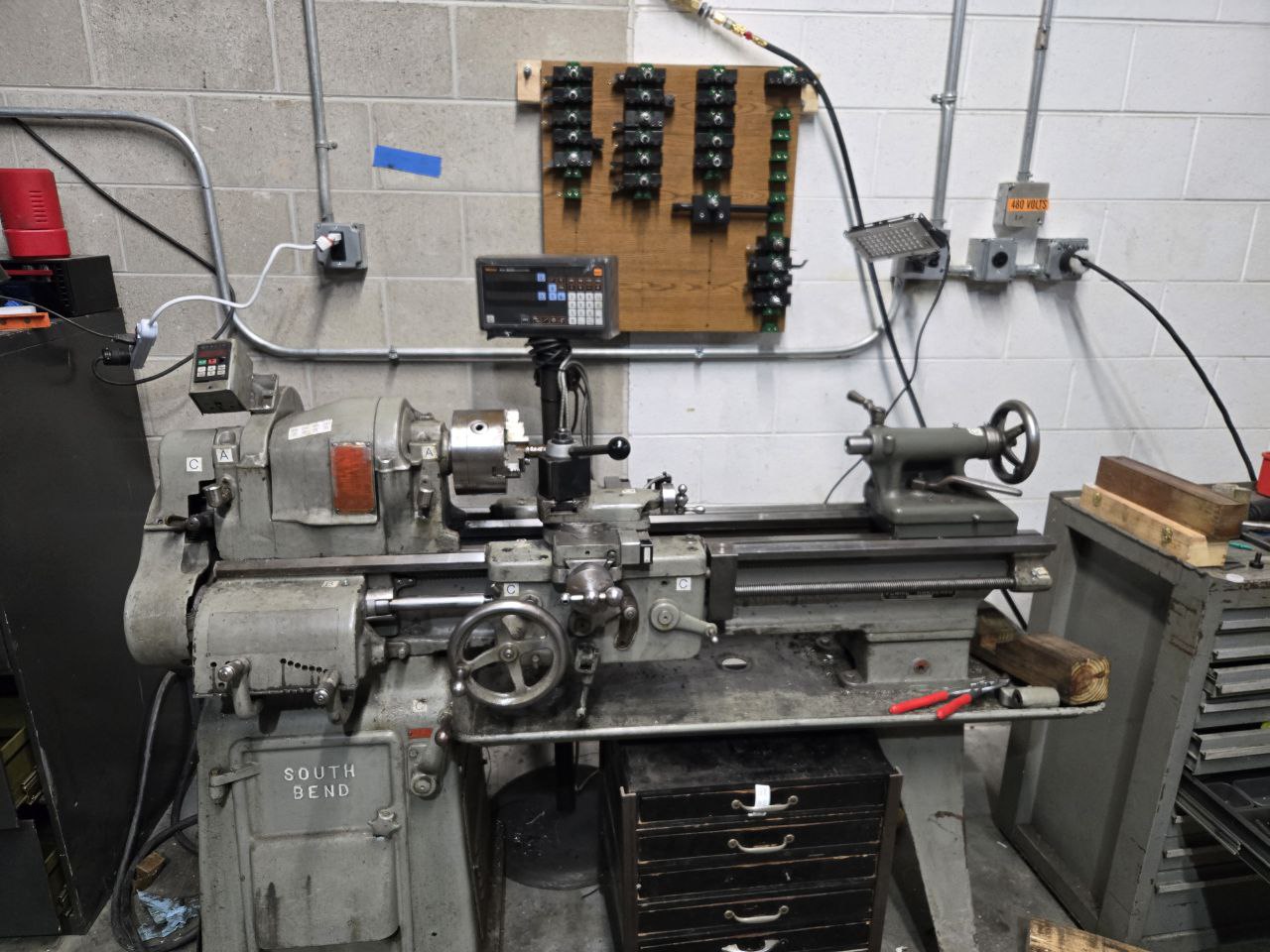

Lathe: Turning, Threading, Polishing, and Repairs

Traditional South Bend lathe, don't let its age fool you; it's still just as accurate, and strong as the day it was made, modernized with a new drive system to allow for variable speeds and better surface finishes.

With its 13" swing and 5' bed, we can turn, thread, repair, or fabricate parts for just about every application. Contact us for further information.

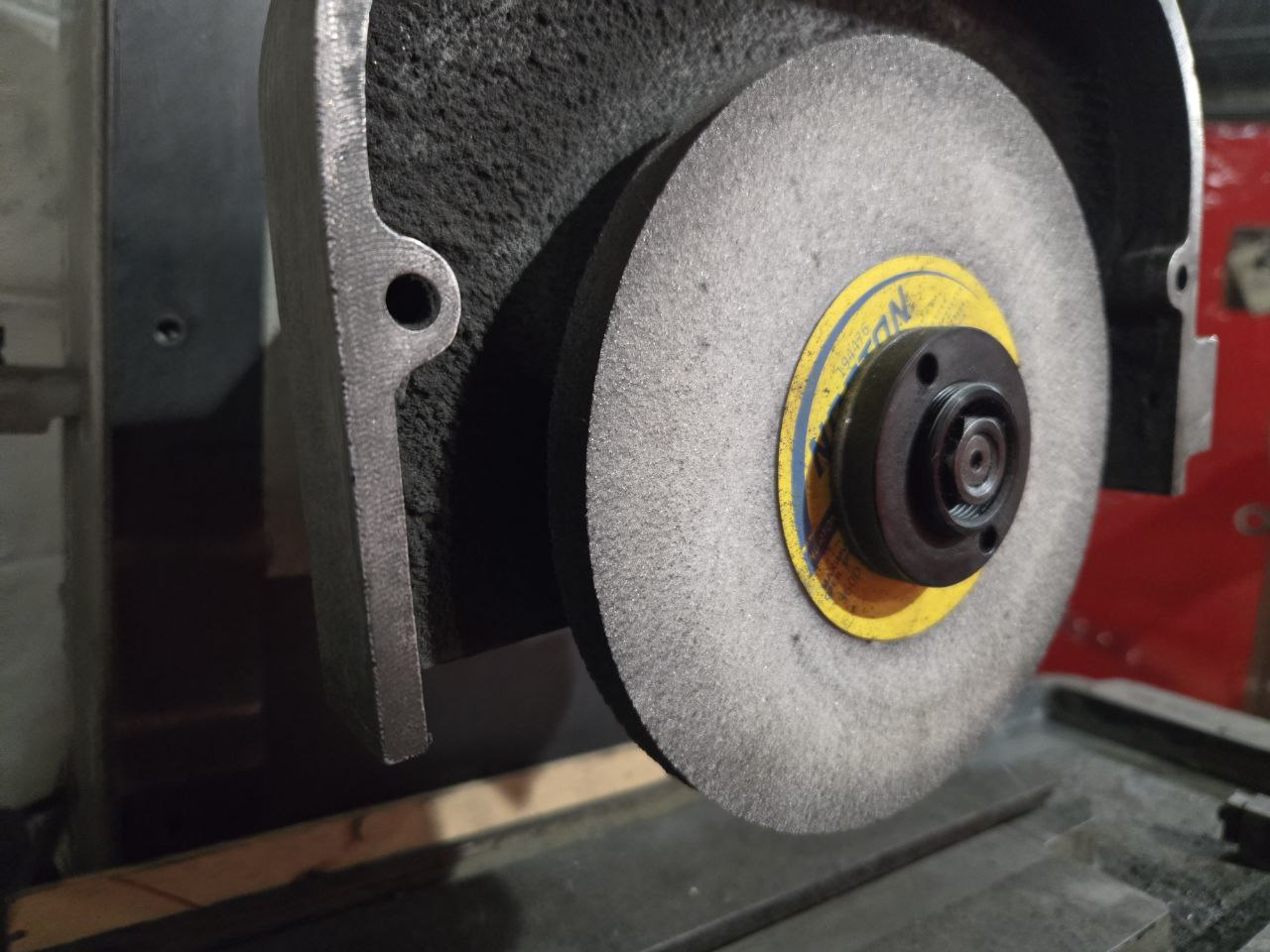

CNC Surface Grinding

Our automated surface grinder has a 12"x6" range and can handle objects up to 12" tall.

Surface grinding is a cost effective way to create truly precision flat or true surfaces, for anything from a ceramic valve seat, to a cylinder head. Using this process also ensures the smoothest and best possible surface finish. Contact us with any questions on this process.